HFlow 1

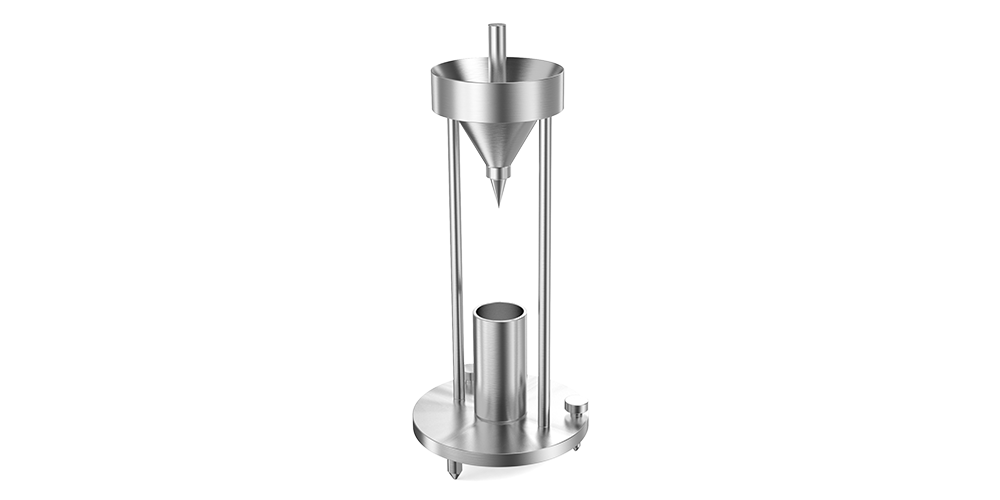

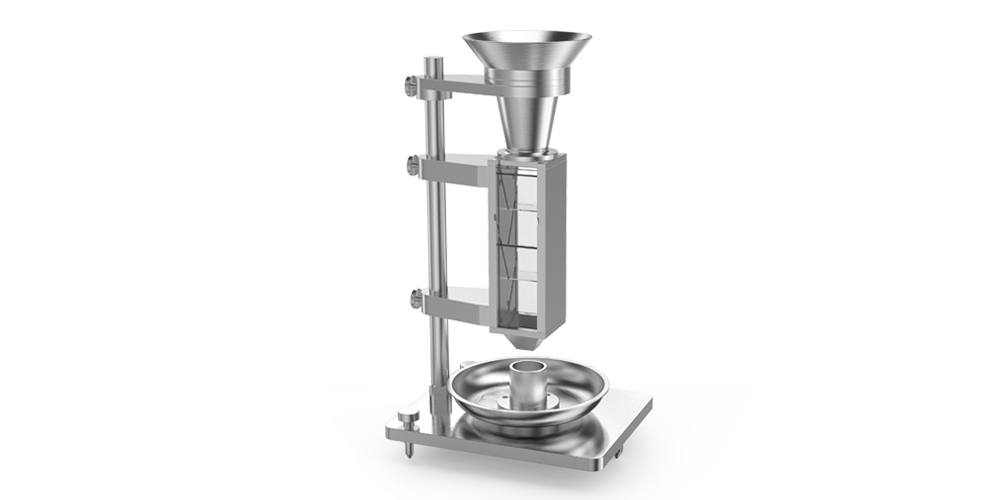

The HFlow 1 flowmeter funnel is a reliable and accurate device to measure bulk density and flow rate in pharmaceutical and metal powders. It allows the sample to flow through a standard Hall funnel, Carney funnel, or Gustavsson funnel, providing precise and reliable measurements of powder flowability. Complied with USP, Ph. Eur., ASTM, and ISO standards, it is ideal for use in laboratories and production facilities working with pharmaceutical and metal powders.

Features and Benefits

- ● Measurement: Bulk density and Flow rate

- ● Technology: Flowmeter Funnel

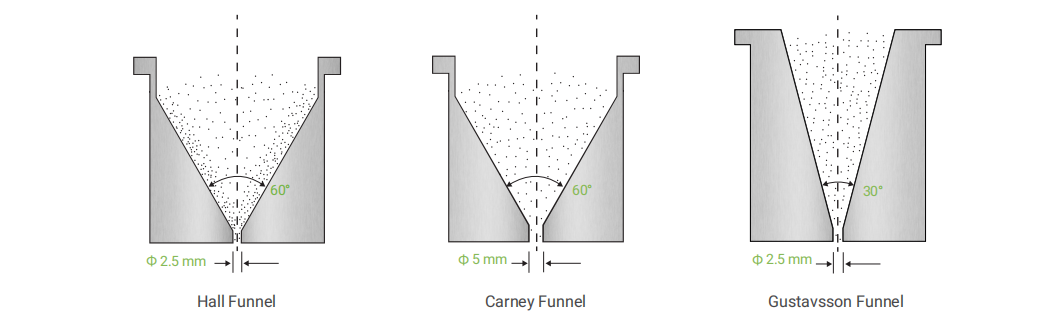

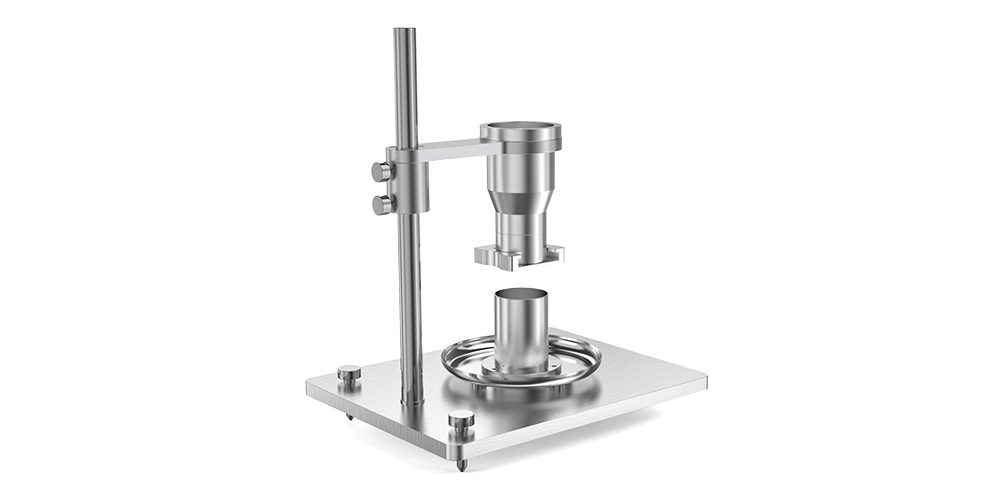

- ● Three funnels: Hall (2.5 mm orifice), Carney (5 mm orifice), and Gustavsson (2.5 mm orifice).

Overview

1. Measurement: Bulk Density and Flow Rate

The HFlow 1 measures both bulk density and flow rate in pharmaceutical and metal powders, offering a choice of three standard funnels—Hall, Carney, and Gustavsson. Complied with USP, Ph. Eur., ASTM, and ISO standards, it accommodates diverse applications, allowing customers to choose the best fit for their measurement requirements.

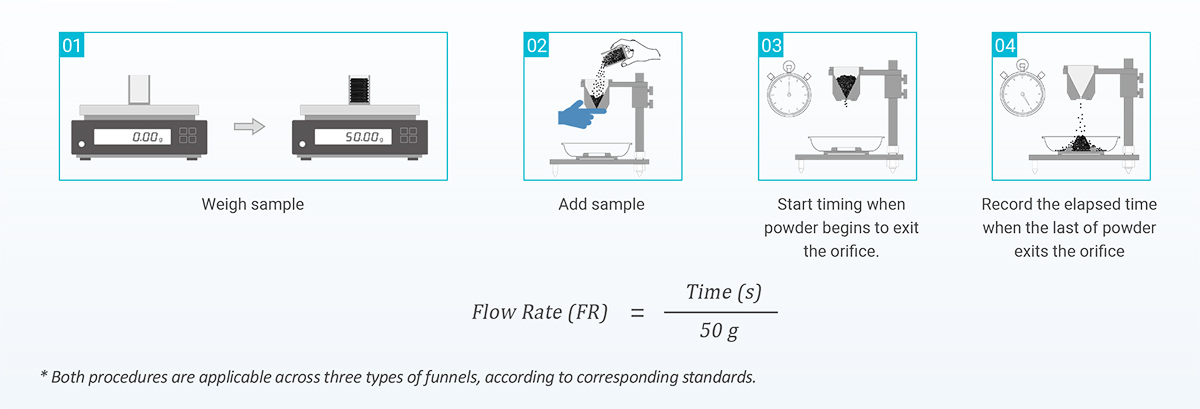

2. Measurement Procedure

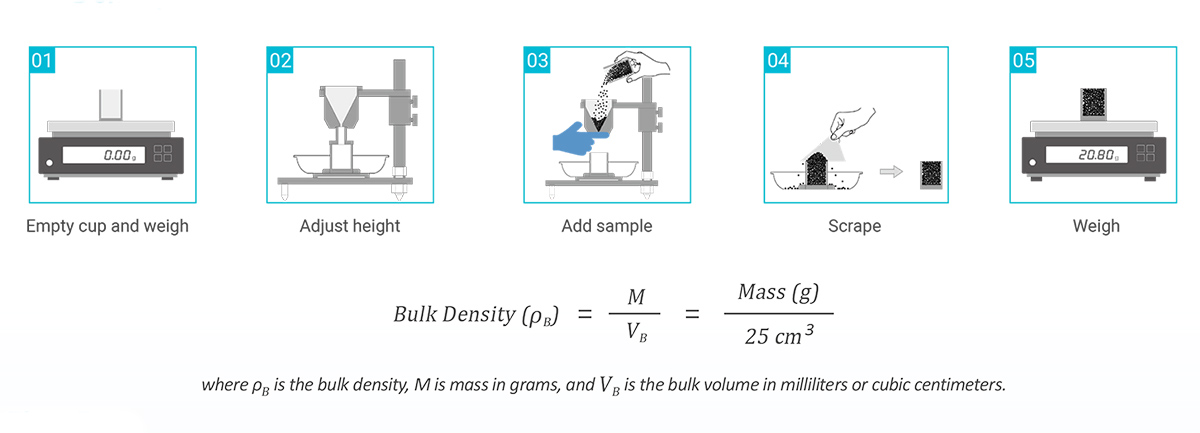

- Bulk Density

- Flow Rate

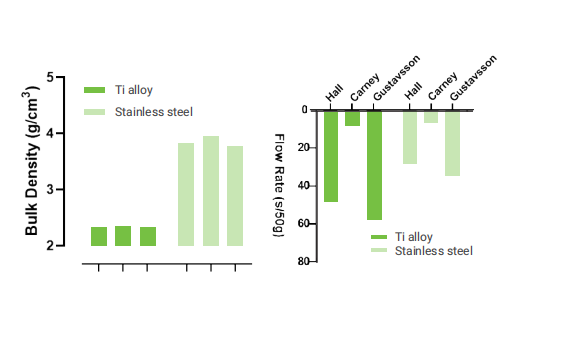

3. Application Example

Analyzing bulk density and flow rate of various metal powders applied in additive manufacturing (AM).

Hall, Carney, and Gustavsson funnels equipped in HFlow 1 have different orifice diameters and angles respectively. They can be employed to test the bulk density and flow rate of a wide range of metal AM powders for evaluating printability.

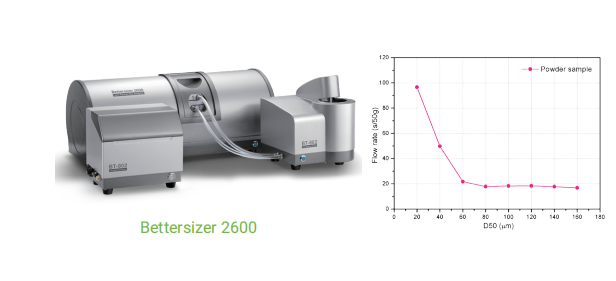

4. Interoperability

The combination of the laser diffraction analyzer Bettersizer 2600 and HFlow 1 assists in balancing the particle size distribution and flow property of AM powders.

In the feedstock preparation process, undersized particles tend to aggregate, which can be detrimental to powder bed fusion processes. The agglomerates will impede the flow behavior of the powder by increasing interparticle friction.

Curated Resources

Related Powder Characteristics Analyzer

-

BeDensi T Pro Series

Tapped Density Tester with a Wallet-Friendly Solution

Number of Workstations: 1-3

Tapping Speed: 100 - 300 taps/min

Repeatability: ≤1% variation

-

PowderPro A1

Automatic Powder Characteristics Tester

Operation Mode: Automatic

Tapping Speed: 50 - 300 taps/min

Repeatability: ≤3% variation

-

BeDensi B1

Bulk Density Tester

Measurement: Bulk Density

Compliance with GB/T 16913

-

BeDensi B1-S

Scott Volumeter

Measurement: Bulk Density

Compliance with USP, Ph. Eur., ASTM, and ISO standards

-

BeDensi P

Bulk Density Tester - Plastic

Measurement: Bulk Density

Compliance with ISO and GB/T standards

-

BeDensi AR

Angle of Repose Tester

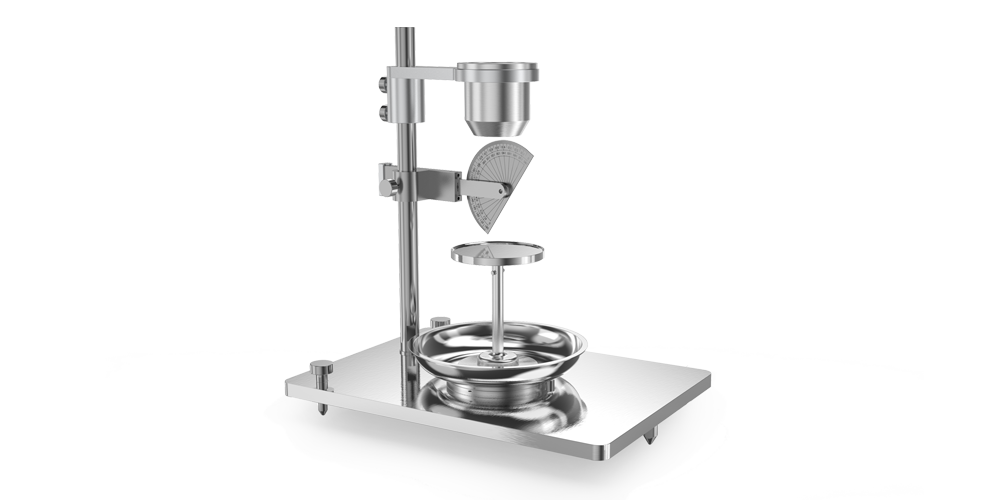

Measurement: Angle of Repose

Compliance with USP and Ph. Eur. standards